Horizontal Plate Freezer

IRL

Mega Food Parks: A Confluence of Innovation, Sustainability, and Investment in India's Food Processing Sector

The Interim Budget for 2024-25 allocated a sum of Rs.1.27 lakh crore for the Agriculture Ministry, marking an increase from the revised estimates of ₹1.16 lakh crore for 2023-24 and the budget estimates of Rs.1.15 lakh crore for the same period.

India’s Finance Minister Nirmala Sitharaman emphasised the government's commitment to enhancing value addition in the agricultural sector and elevating farmers' income, stating that efforts in this regard will be intensified. Sitharaman further stated that there will be investments directed towards post-harvest activities, encompassing aggregation, modern storage, efficient supply chains, primary and secondary processing, as well as marketing and branding.

India, a significant agricultural producer, faces challenges with low value addition to its agricultural produce. In response, the Mega Food Park Scheme aims to elevate value addition through food processing while also tackling post-harvest losses and fostering rural employment. This initiative anticipates substantial benefits for the Indian economy, projecting an annual rise of Rs. 10,000 crores in agricultural produce value addition and the creation of job opportunities for approximately 10 lakh individuals. Additionally, the scheme targets a 20% reduction in post-harvest losses.

Positioned as a pivotal government endeavour to bolster food processing in India, the Mega Food Park Scheme is poised to deliver multiple advantages, including heightened agricultural value addition, diminished post-harvest losses, and augmented employment prospects in rural regions.

What Are Food Parks and Why Are They Popping Up Across India?

In 2008, the Ministry of Food Processing Industries (MoFPI) introduced The Mega Food Park Scheme (MFPS) to facilitate food processing in India. Since its inception, the MFPS aims to establish direct connection between farmers and processors, minimising food waste, and boosting the export of processed food products from India.

This initiative led by the government seeks to establish high-quality food processing infrastructure nationwide, including manufacturing units, cold storage facilities, packaging units, quality control laboratories, logistics support, and administrative services.

Food parks play a crucial role in enhancing the value of agricultural produce by offering facilities for processing, packaging, and preservation. This not only extends the shelf life of perishable goods but also boosts their marketability, leading to higher returns for farmers and agribusinesses.

The scheme operates with multifaceted objectives in mind. Firstly, it creates a direct linkage between agricultural production and market access by facilitating collaboration among farmers, processors, and retailers. This integration not only streamlines supply chains but also enhances market responsiveness to agricultural yields. Moreover, the MFPS elevates value addition within the food processing sector, thereby bolstering the economic viability of agricultural activities.

By promoting food processing activities, they contribute to rural development, stimulate entrepreneurship, and foster infrastructure growth. Moreover, food parks provide small and medium-sized enterprises access to modern infrastructure and market networks, enhancing their competitiveness domestically and internationally.

Food parks play a crucial role in enhancing the value of agricultural produce by offering facilities for processing, packaging, and preservation. This not only extends the shelf life of perishable goods but also boosts their marketability, leading to higher returns for farmers and agribusinesses.

Know how “A Mega Food Park with Cold Storage Facility is Changing Lives of Tribal People in Mangrol, Surat” In this blog by Gaon Connection.

With over 24 mega food parks already operational across the nation and having collectively generated over 100,000 jobs, the MFPS stands as a testament to its transformative impact,creating a paradigm shift in India's food processing landscape.

The inaugural mega food park in India, Srini Mega Food Park, is situated in Chittoor, Andhra Pradesh. To facilitate the establishment of these mega food parks, the Ministry of Food Processing Industries (MoFPI) extends financial assistance to the consortium of companies. This assistance comprises both grants and loans, with grants totaling up to Rs. 50 crore and loans extending up to Rs. 200 crore. The consortium of companies is required to contribute the remaining funds.

The financial assistance provided by the MFPS, up to Rs. 50 crore per mega food park, is utilised for various purposes such as land acquisition, construction of infrastructure facilities like cold storage and processing units, marketing strategies, and training programs for farmers and processors.

As of March 2023, the government has approved 42 mega food parks, with 37 operational ones, generating over 1 lakh jobs and substantially aiding the growth of the food processing sector in India.

The MFPS has the potential to foster growth in the Indian economy, while improving the livelihoods of farmers and rural workers. Continued government support, and collaboration with the private sector are essential to realising this potential and driving innovation in food processing technologies.

Preserving Freshness with the Power of Flake Ice in Industrial Refrigeration

Where there is fish stored, there has to be ice. Keep it fresh, Keep it cool, with IRL’s Flake Ice Machine.

Flake ice is known for its cleanliness and purity, making it ideal for food-related applications. Unlike other forms of ice, flake ice is made using a process that eliminates impurities and ensures high levels of hygiene, making it safe for direct contact with food products. The irregular shape and thinness of flake ice allow for more uniform cooling of products compared to other types of ice. This helps prevent hot spots and ensures consistent temperature control, which is crucial for preserving the quality and freshness of perishable goods.

Flake-ice is considered to be highly economical over crushed ice which melts at a higher rate during loading and storage. Large surface area-to-volume ratio of flake ice allows it to cool products more quickly than other types of ice. It is easy to dispense and distribute which makes it convenient for various applications, from filling beverage glasses to packing and shipping perishable goods.This rapid cooling property and versatility of flake ice ensures maximum freshness and preserves the quality of the fresh produce.

Upon impact with the product, flake ice does not cause damage to the product itself; instead, the ice breaks upon contact, safeguarding the integrity of the product. The softness and moldability of flake ice makes it ideal for applications where conformability is necessary, such as in physical therapy or cold therapy packs. Flake-ice holds less than 2% residual water content making it dry and the coldest form of ice. It has irregular fragments of ice with a variable thickness that can be adjusted between 1 to 2 mm.

These features of Flake-Ice make its application ideal for industrial processes, fish & seafood display cabinets in supermarkets, transportation of perishable goods, as well as for optimising dough temperature in the baking industry.

What makes Industrial Refrigeration Pvt. Ltd. Flake Ice Machine Reliable & Durable?

Several decades ago, Industrial Refrigeration Pvt. Ltd. (IRPL) recognised this difference and pioneered the application of flake-ice to the seafood industry, long before the Government of India made it mandatory (HACCP) for its use in the export oriented fish processing industry.

IRPL also offers complete food processing plants, Individual Quick Freezers (IQFs) & ultra modern multi product cold storages on a near-turnkey basis, having successfully executed several turnkey and ice making projects across India and overseas. This includes 10 ice-makers projects of 10 tons, each installed under one roof for a seafood park in Kerala and one for a fishing harbour in Oman. IRPL offers a complete flake-ice plant (generator drum + refrigeration system), or separate ice generators in case a refrigeration system preexists in your premises.

Features:

- Scientific design inspired from years of engineering experience

- Quick ice production

- Safety and sanitation

- High reliability and low breakdown rate

- Compact design

- High efficiency and energy saving

- Simple maintenance and convenient operation

- Great adaptability

- Outstanding electric control system

Whether you need a standalone unit for a small seafood display cabinet or a large-scale flake ice plant for industrial processing, there are options available to meet your specific requirements.Our in-house refrigeration solutions (particularly for food processing) draws upon engineering expertise from leading global companies in Freezing Technology to keep abreast of the technological innovations.

Technological Specifications:

Medium-sized flake ice machine model and performance parameter

| MODEL | CAPACITY | REFRIGERATION CAPACITY | EVAPORATING TEMP. | REDUCER POWER | CIRCULATING PUMP POWER | COMPRESSOR | WEIGHT |

| IR30 | 3000 kg/d | 14100 kcal | -22 ℃ | 0.37kw | 0.03kw | 12hp | 1022 kg |

| IR40 | 4000 kg/d | 18800 kcal | -22 ℃ | 0.37kw | 0.03kw | 20hp | 1117 kg |

| IR50 | 5000 kg/d | 23500 kcal | -22 ℃ | 0.55kw | 0.12kw | 25hp | 1168 kg |

| IR60 | 6000 kg/d | 28200 kcal | -22 ℃ | 0.55kw | 0.12kw | 30hp | 1168 kg |

| IR80 | 8000 kg/d | 37600 kcal | -22 ℃ | 0.75kw | 0.25kw | 40hp | 1650 kg |

| IR100 | 10000 kg/d | 47000 kcal | -25 ℃ | 0.75kw | 0.25kw | 50hp | 1742 kg |

★ Note: For non-standard demand, please inform us of the details.

Headquartered in Mumbai, IRPL is a part of the 65 year old ALLSTATE Group involved in Refrigeration, Transformers, Leisure Equipment, Software & Media. Some of our group companies have agreements with Fortune 500 Companies viz Fuji, Agfa, Chemours (Du Pont), and other International Companies.

Guide To Select The Perfect Cold Room

Selecting a cold storage which best fits your requirements can be perplexing. There are major concerns like costs, energy efficiency, maintainability, ability of the storage to maintain stable temperatures year by year etc.

Cold storage manufacturers make cold rooms of different measurements, equipped with various features and components to suit the requirements of the buyer. To give you an idea, an industrial freezer room can keep temperatures in the range of -60°C to 15°C.

You need to address a number of aspects before deciding to buy a cold room. Our team at IRL will be more than happy to guide you through these concerns.

- Purpose of the cold room

For what purpose you wish to buy the cold storage? Do you need a laboratory cold room for pharmaceutical requirements or a commercial cold room for the needs of hospitality industry?

An industrial cold room not only safeguards seafood, farm produce, other horticultural/agricultural supplies and pharmaceuticals, but it can also preserves operational IT servers & equipment whose performance and lifespan get adversely affected by the heat they generate.

Food processing, hospitality, entertainment, supermarkets, chemical industry, oil & gas industry, and manufacturing industry find wide applications of cold rooms that are durable, hard-wearing, easy-to-maintain & easy-to-clean. You can reach out to our team of experts at IRL, a cold storage room manufacturer, for any assistance to arrive at the best fit for your cold storage requirements.

- Capacity of the cold storage

Your operational prerequisite should determine this aspect. How quickly your stock is spent indicates the capacity of cold room you need.

The size of your cold storage should exceed the bulk of stock you wish to preserve. It should have ample space for racks, shelves, aisle space to roll bulk of food items in and out, airflow etc. Volume of the products, gap between the wall, pile and ceiling – all these aspects need attention.

The cold storage manufacturing companies recommend installing larger cold room (which is around 40% larger than your need) than installing many smaller cold storages to provide the equivalent chilling facility. Standard height of a cold room is well over 2 meters.

Also, with smaller cold rooms, a time eventually comes when the stock is cramped due to lack of space or it gets degraded due to poor aeration. Although, a smaller cold storage is suitable if you are running a restaurant.

Bear in mind that under-utilizing an industrial cold room doesn’t reduce its operating costs.

- Temperature range needed in the cold storage

You must understand that different stock requires different range of temperature for preservation.

For instance, items to be preserved for shorter duration like vegetables, fruits, cooked meat, natural product, milk, cream baked goods, sauces etc. must be stored at temperatures around 3°C to 12°C to prevent microbial action.

Raw seafood, meats and some dairy items require temperature range from -3°C to 4°C. For longer duration storage of raw food material (like solidified veggies, meat, chicken, dessert, bread, pasties etc.), temperature must be maintained from -5°C to -20°C.

Similarly, a pharma organization would employ a pharmaceutical cold room for preserving different under-trial medicines which require different temperatures for storage.

- Features & accessories

- Panels & insulations: Cold storage constructed on site should have wall panel insulation rating of R-30 (i.e. a 4-inch thickness). Panels (of walls, ceilings and floors) are most commonly equipped with polyurethane for insulation from the inside while the outside panels may be of stainless steel (most expensive) or aluminum (least expensive, most weather resistant & thus most popular choice).

- Lighting: There should be adequate lighting (LED preferably) in the interiors of the cold room. The staff must be able to turn on the lights both from the inside and from the outside of the storage. The light bulbs inside the cooler should be unbreakable and vapor proof. LED bulbs consume 90% lesser energy than traditional incandescent bulbs.

- Door: The door of the cold storage should open to the outside and should come with a heavy-duty door closer and self-closing, cam-lift door hinges. The cam keeps the door opened if it opened past 90° angle. The door should have an interior safety release mechanism so that a person doesn’t get accidently locked inside the cooler. Strip curtains (made of transparent or tinted PVC) on the doors act as an extra barrier to keep the cold air inside and the hot air & unwanted airborne particles from coming in.

- Alarm system: It is wise to equip the cold storage with an alarm system to notify you of sudden variations in temperatures inside the cooler. For instance, if a door is left open for a long time, the system would detect it and alarm you.

- Thermometers:: Consider placing multiple thermometers in strategic areas of the cold storage to ensure a consistent temperature is maintained inside the interior of the storage. Thermometers can be coupled with a data logger which records & organizes the temperature data in spreadsheets that are accessible online for download.

- Flooring: You can get installed a protected floor which ensures a stable temperature inside the cold storage. This is certainly an added advantage in hotter situations.

You can also have other accessories like a foot treadle to open the door with your foot if your hands are full, or a non-skid tape around the freeing area so that one does not slip or skid accidently.

Purchase cost increases with the number of features you wish to be added in your cold storage.

- Refrigeration system of the cold storage

A cold storage or walk-in freezer has an evaporator to draw out the heat from the cold room’s interiors and a condenser which discharges the hot air. If you require your cold room to be a solitary temperature zone, pick clip-on refrigeration.

Then, there is the remote refrigeration framework which isolates the evaporator and the condenser units by linking them through pipelines. This architecture is better at discharging the heat & thus excellent for extensive storage spaces.

If you want multiple cold rooms for vast operations, then a centralized refrigeration system will be the best option to cool all of them.

- Cold storage’s energy efficiency

A cold storage with high-efficiency compressor yields energy savings of 4-10%, electronically commutated condenser or evaporator fan motors can further save 3-19% in energy; LED lighting, polyurethane foam-based proper structural insulation (25mm thick usually), automated door & excellent sealing – all of these combined can make your cold storage, on an average, 12% more energy efficient.

As compared to a smaller cold room, the air inside a larger cold storage warms up slower i.e. the temperature inside a larger one remains stable for a longer time. So, to maintain the optimum operating temperature, the cooling system needn’t work that hard.

Obviously, it is more energy-efficient to operate one cold room instead of many smaller ones. The only question is whether that one cold room meets all your storage requirements.

Depending on the stock turnover, outside temperature, temperature of the incoming product & the usage of the cold storage, the energy consumption of a cold storage ranges from 30kWh/m3/year to 50kWh/m3/year. You can calculate the yearly cost of operating the cold room based on the electricity charges in your area.

- Be ready to deal with regular maintenance

Cold storage manufacturers always recommend regular maintenance for a longer service life of your cold storage. It can help you save around 5% of your energy costs.

Frequent checks of the cold storage components like the cooling unit, thermometers, lighting, ventilation system, alarm system etc. ensure that your cold storage is running healthy. Even the door not closing fully can drastically debilitate the optimal functioning of the cold storage.

We re-emphasize that regular checks & fine-tuning are still cheaper in the long run instead of dealing with a storage breakdown someday which forces you to purchase another cold storage. Do enquire who would be providing the maintenance.

- Customized cold room

You can avoid buying a standard cold room and purchase a customized one tailored to your needs. It can have glass doors, noiseless gathering unit, skid-proof floor, customized racks, dedicated insulations for sections etc. Cost will be a bit more but that is a one-time spending. If it suits your needs, go for it.

- Manufacturers/Suppliers

There are cold storage manufacturers who sell commercial cold storages locally and there are those who sell it internationally as well, with variations in quality, pricing, compliance with standards, and designs.

It is always good to research why a cold storage supplier is recommending you a particular manufacturer.

Do take the initiative to reach out to the cold storage manufacturer on calls or emails. Browse through their websites to get an idea of their products and whether they might suit your business requirements.

- Warrantee, guarantee and safety

Ask your cold storage dealer if the panels, refrigeration & the cooling hardware etc. are covered under warranty. Discuss with them whether an extended warranty plan will be more cost effective, considering any damage or malfunctioning of the equipment in future.

Try to go for cold room manufacturers offering a guarantee of more than 2 years.

Inspect & acquaint yourself with the safety standard of the prospective cold storage. Enquire about it in depth from the cold room supplier.

Industrial Refrigeration Pvt. Ltd. (IRL) is a pioneer in providing commercial cold storage systems for hospitality, supermarket, pharma and other sectors to cool or freeze food, beverage, meat, fruits and vegetables, chemical or other goods.

Different standard dimensions of cold-room length, width, height for the walk in cooler or walk in freezer and chiller are available at IRL.

We also supply modular walk in freezer & cold room which can easily be disassembled & reassembled if its relocation is required. The cold room panel of our commercial cold room is made of high density (40kg/m3) polyurethane for good insulation. Our cold rooms come with cam lock tongue and groove panel with gasket which ensure perfect sealing of the cold room whereas a digital thermostat enables precise temperature control.

Feel free to get in touch with us for all your cold storage requirements.

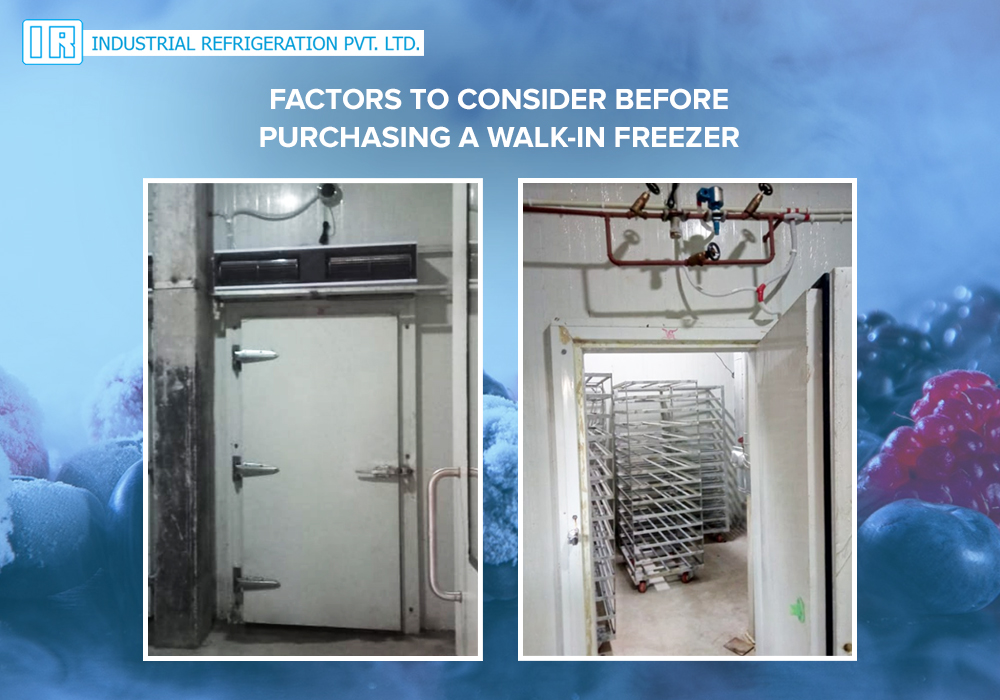

Factors To Consider Before Purchasing A Walk-in Freezer

Operating a restaurant, café, supermarket, bar, pub or any other similar establishment requires investing in a commercial walk in cooler or walk in freezer to preserve the perishable inventory for longer durations.

Selecting the right walk in freezer for business can impact it positively in the long term. Thus, it mandates a deep analysis of your cooling/freezing requirements to match them with the best walk in cooler.

Before You Decide to Buy That Walk in Freezer…

Here are the predominant aspects for your consideration before making the final call on a commercial walk in cooler for your business.

- Utility

If it is food items you wish to preserve for longer times, clearly identify whether you need a freezer to freeze the food items (< 0°F), or a refrigerator to just cool the food items (between 35°F and 41°F). Depending on the utility, you may need display coolers, floral refrigerators, meat and game lockers (hunting purposes), brew caves in residential bars or setting up a cold storage in warehouses. Each utility must be addressed accordingly.

For instance, kitchens serving 400+ meals daily usually need three walk in refrigerators: one for produce (41°F), one for meats and fish (33°F to 38°F), and one for dairy products (32°F to 41°F).

- Address the capacity requirements

Bear in mind that it’s not possible to use every sq. ft. of the interior of the commercial walk in freezer. You’ll need space for racks, shelves, aisle space to roll bulk of food items in and out, airflow etc.

A rule of thumb is to assign 1.5 cubic feet of walk in storage for every meal served per day. Make an informed guesstimate about the linear feet of shelving you’ll need in every section of the walk in freezer and add 40%-50% to it to account for overflow volume increases and loose products. Then multiply this space with the depth of the shelf to arrive at the total 3-D space you’ll need.

However, remember that operating costs increase as the size of the freezer increases. The team of experts at IRL can assist you to optimally meet all your freezing or cooling requirements.

- Outdoor walk in freezer vs indoor walk in freezer

You may want to install an outdoor walk in cooler or outdoor walk in freezer when space is at a premium and you don’t need to increase your kitchen’s size. Outdoor walk in freezers are money savers as their installation cost is about 50% lesser than that for indoor kitchen walk in freezers. Also, they vent the heat outside the building and make it very easy to receive food deliveries.

Indoor installations are tricky. You have to manage the already limited space you are available with. Indoor walk in coolers that are self-contained generate a lot of heat to power the cooling system, straining the HVAC system. Clearly, not suitable for a hot & humid location.

- Features & accessories

- Levelling: As carts are often wheeled in and out of the walk in freezer, its floor should be at level with the floor of the location where it is installed. This is achieved by using strips called screeds, applied to the floor.

- Panels & insulations: Coolers constructed on site should have wall panel insulation rating of R-30 (i.e. a 4-inch thickness). Panels (of walls, ceilings and floors) are most commonly equipped with polyurethane for insulation from the inside while the outside panels may be of stainless steel (most expensive) or aluminum (least expensive, most weather resistant & thus most popular choice).

- Interior lighting: The installer should ensure adequate lighting in the interiors of the walk in cooler. You must be able to turn on the light both from the outside as well as the inside of the cooler, with a LIGHT ON indicator outside. The light bulbs inside the cooler should be unbreakable and vapor proof. LED bulbs consume 90% lesser energy than traditional incandescent bulbs.

- Compressor: A compressor of at least 2 horsepower is needed for a 9 sq. ft. walk in freezer. The condenser unit may be located either on top of the walk in directly above the evaporator or around 25 feet away with lines connecting it to the walk in freezer (a remote system). The latter configuration is common in capacities of up to 7.5 horsepower.

- Door: The door of the cooler should open out and should come with a heavy-duty door closer and self-closing, cam-lift door hinges. The cam keeps the door opened if it opened past 90° angle. The door should have an interior safety release mechanism so that a person doesn’t get accidently locked inside the cooler. Strip curtains (made of transparent or tinted PVC) on the doors act as an extra barrier to keep the cold air inside and the hot air & unwanted airborne particles from coming in.

- Shelves: Consider installing epoxy-coated wire shelves that are more durable. They are also rust and water resistant.

- Thermometers: Consider placing multiple thermometers in strategic areas of the cooler to ensure a consistent temperature is maintained inside the interior of the walk in cooler/freezer. Thermometers can be coupled with a data logger which records & organizes the temperature data in spreadsheets that are accessible online for download.

- Alarm system: It is wise to equip the walk in freezer with an alarm system to notify you of sudden variations in temperatures inside the cooler. For instance, if a door is left open for a long time, the system would detect it and alarm you.

- Non-skid tape: When working around a freezing area, skidding and slipping can’t be ruled out. To ensure the safety of everyone walking in and out of the freezer, use non-skid tape on the freezer’s floor.

- Foot treadle: When both your hands are full, it would be a real blessing if you could open the door with your foot by pressing a pedal or lever!

- Ease of use

The walk in cooler must be easy to use by your staff so that they can make the best & most of it. The cooler should be easily programmable & its temperature display should be easy to read so that the interior temperature can be regularly and correctly monitored. The doors should open & close smoothly & should have a safety mechanism so that nobody gets trapped inside the cooler.

- Adequate ventilation

Poor ventilation will strain the compressor to work extra to draw hotter air away from the cooling unit. An ambient temperature of no more than 80°F is good to go around the compressor. There should be a provision of adequate space (up to 1 feet) around the top, rear & sides of the unit so that fresh air is constantly available for the compressor. You must consider remote compressor system if adequate space is not available.

- Quality

Obviously, a cheap walk in freezer can be a financial liability in the long term owing to frequent repair costs (or replacements). It can inflate your electricity bill due to poor power efficiency. LED lightings are costly, no doubt, but it will save you costs over the life of the walk in freezer. Do research about the available insulations. Get a clear idea of how much of the R-value will be retained over a considerable period of cooler’s operation.

- Manufacturers

There are manufacturers who sell commercial walk in freezers locally and there are some who sell it internationally as well, with variations in quality, pricing, compliance with standards, and designs. It is always good to ask why a walk in cooler supplier is recommending a particular manufacturer. Do take the initiative to reach out to the manufacturers on calls or emails. Browse through their websites.

- Warranty

Ask your dealer if the panels, refrigeration & walk in cooler hardware etc. are covered under warranty. Will an extended warranty plan be more cost effective, considering any damage or malfunctioning of the equipment?

- Maintainability

The walk in cooler should be easy to maintain, clean & repair whenever needed.

Industrial Refrigeration Pvt. Ltd. (IRL) is a pioneer in providing commercial walk in freezer systems for hospitality, supermarket, pharma and other sectors to cool or freeze food, beverage, meat, fruit, vegetable, chemical or other goods.

Different standard dimensions of cold-room length, width, height for the walk in cooler or walk in freezer and chiller are available at IRL.

The modular walk in freezer & cooler cold room can easily be disassembled and reassembled if its relocation is required. The cold room panel of our commercial walk in freezer and walk in cooler chamber is made of high density (40kg/m3) polyurethane for good insulation.

Cam lock tongue and groove panel cold room design with gasket ensure perfect sealing of the walk in cooler & walk in freezer whereas a digital thermostat enables precise temperature control.

We have years of experience manufacturing walk-ins for a wide variety of uses and industries like:

- Convenience - Display Coolers & Caves;

- Restaurant - Foodservice Walk-Ins;

- Floral - Floral Refrigerators;

- Grocery - Storage Coolers & Freezers;

- Hunting - Meat & Game Lockers;

- Residential Bars - Brew Caves;

- Warehouse - Cold Storage Warehouses etc.

For an exhaustive account of how we help industries effectively meet their cooling and freezing requirements, feel free to contact us at IRL.

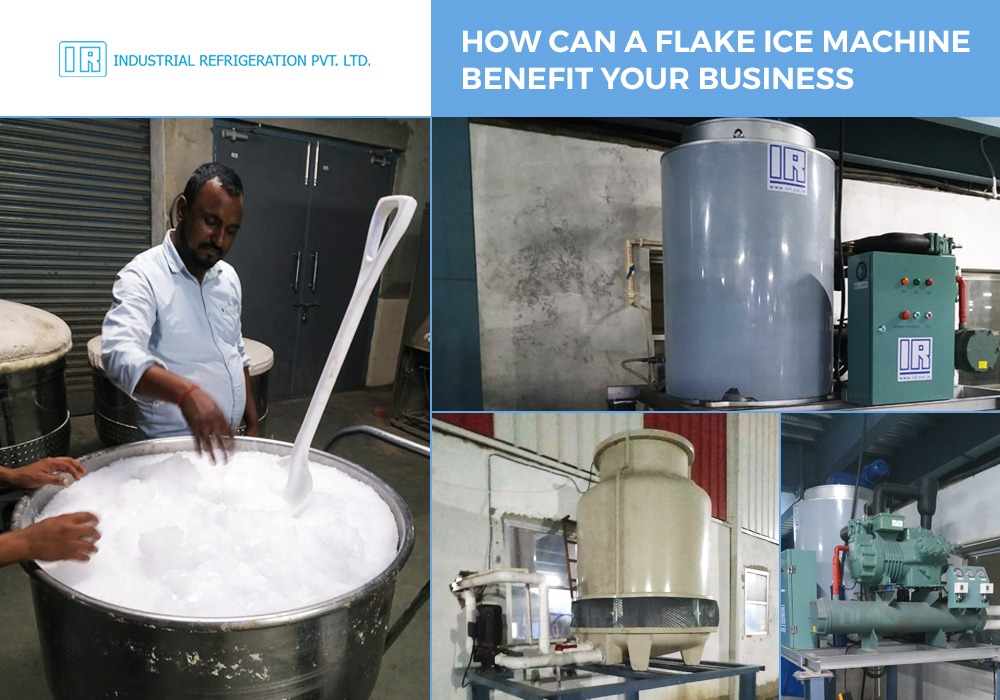

How Can A Flake Ice Machine Benefit Your Business

Ice-flake making machines find utility in many market segments. Depending on the nature of applications, the best ice making machines generate types of ice such as cube ice, flake ice, nugget ice etc. in huge amounts daily worldwide.

These ice types cater to the varied requirements ranging from preservation of aquatic produce to stem cells storage.

Flake ice is perhaps the most efficient form of ice from a diverse utility standpoint.

Here is why:

What is Flake Ice?

Flake ice is a light, airy, moldable form of ice that can stick to itself. Flake ice maker machines generate this ice at temperatures varying from -5°C to -8°C.

Flake ice is easier to work with and it finds diverse applications over numerous fields (like fisheries) as discussed ahead.

Flake Ice Machine for Different Industries

Food Processing

- Dairies

Ice flake machines are used in cooling storage tanks & the icing of the delivery trucks of the dairy industry to preserve milk products like cheese, yogurt, butter, cream & ice cream. These products are temperature sensitive and require appropriate temperatures to prolong their shelf lives.

The milk is stored for at most 2 days at below 40°F temperatures in the cooling storage tanks after which it undergoes homogenization, pasteurization, packaging & shipping. The chillers arrest deterioration of the milk molecules, facilitating the manufacturing of above mentioned dairy products from it.

- Fruits & vegetable produce

Maintenance of freshness of fruits & vegetables till they are bought by the customers is a big challenge in this industry. Wrong temperatures may damage the produce or, worse, cause it to rot.

On-farm flake ice maker machines come to the rescue. Due to the relatively larger contact area of the flake ice and lesser sharp edges, the harvested produce can be cooled exceptionally fast without any significant damage to the surface of the fruits or the veggies. Before shipment of the pre-cooled produce, flake ice is used in top icing to ensure preservation of the produce’s structural integrity & freshness.

- Fisheries

As seafood resources are depleting, fishermen are making longer fishing expeditions which makes it critical to have flake ice making machine on board the ship to preserve the fish for longer times since fishes start decomposing rapidly immediately after getting caught. This demands that the fishes be kept uniformly at around 0°C which is easily accomplished by the flake ice produced by the machine onboard the ship. Due to its soft nature, the flake ice doesn’t bruise or injure the fish during storage and it keeps the haul fresh at every level of the supply chain till it arrives at the local market.

Land-based seafood processing plants, storage facilities etc. also employ flake ice making machines so that no unchilled fish is accumulated at any point of time.

Food Displays

Flake ice is soft, moldable & uniform which makes it best suited for creating appealing displays. It is an excellent choice for retail displays like seafood counters at supermarkets. Supermarkets employ flake ice machine for fish, fruits, veggies & a lot of other food items that must be consumed within a short period.

Passively refrigerated open beds are also used in supermarkets for presenting the produce to the customers. Food products must inspire trust among the customers about freshness. The food items are nestled in flake ice displays which are good for aesthetics as well as cooling.

Due to the softness of the ice flakes, there is no risk of blemishes on the food items. The snow like texture of the flakes & their easy molding ability renders the ice flakes highly useful in blanketing perishable items like seafood on display in any shape one wishes for.

Buffet displays are cooled efficiently & evenly by the flaked ice. As the contact area of flaked ice is larger, it lasts longer.

Confectionery

Just like the dairies, a confectionery also needs a flake ice machine. In order prevent the flour from leavening during the mixing of flour & milk for baking a confectionery item such as cake or pastry, flake ice is used as an ingredient. Its thinness allows it to melt quickly, completely & evenly so that no air pockets remain in the mixture. This prolongs the life of the batter. On the other hand, using chip ice often results in uneven cooling of the batter, residual ice & air pockets in the batter.

The flake ice is best suited to control yeast growth during the production of bread. Owing to its even melting behavior, easy handling as compared to handling chilled water, & excellent cooling qualities, it is widely used in the production of pies, pastries & pasties.

Medical Sector

The medical sector uses refrigeration not only for vaccines but also to preserve and store organs & stem cells. For the latter purpose, flake ice serves best. Also, the medical staff uses flake ice to treat sprain and other related injuries.

There are many other applications of flaked ice.

As flake ice has larger contact area, it provides an excellent way for rapid cooling of the laboratory work. Its easily moldable nature makes flake ice the perfect choice for use in physical therapy treatments like ice baths & cooling packs, although more relevant for ice baths since the residual water content of flake ice has more adhesive nature. This makes it suitable for use in processes where faster heat transfer is the requirement.

Construction Sector

A relatively unknown fact is that concrete mix also requires the right temperature during its transportation and usage. Flake ice in concrete cooling process is used as a direct source of water to reduce cracking of concrete. The ice is mixed and poured at constant and low temperature in the mass concrete mixture which finds utility in projects of hydro dams, nuclear power plants etc.

When the concrete is cured, it generates lot of heat. Flake ice is used to reduce & control this heat thereby regulating the temperature of the concrete mix at the desired level for specific construction projects. If the temperature of the concrete mix is not regulated, it can compromise the structural integrity of a project.

Flake ice, being thinner, melts quickly in the concrete mix & leaves no large ice particles or voids, which is usually the case if chipped ice is used. Due to its adhesiveness and longer life, flake ice is the ideal choice when the concrete production has to be delayed for some reason.

As the flake ice production doesn’t require excess water disposal, the ice flaker machine can be set up quickly and in a little space near the construction site.

Hospitality: Bars & restaurants

The hospitality industry is all about aesthetics & ambiance of the place & freshness of the food dishes served.

Salads, seafood bars, drink displays, cocktails, drink tubs, fruits juices … flake ice makes these delicacies only better at restaurants and bars. The moldable flake ice is ideal for use in seafood bars. One can create eye-catching shellfish & raw fish selections using flake ice for customers.

High end restaurants employ the best flake ice machine for stocking quality flake to create dazzling food presentations in front of the customers.

At bars, bottles of beverages & cans stay in place amid the flake ice sticks (owing to flake ice’s moldable nature) and remain cool for a longer time. While blending the beverages, the crushed hard ice cubes can not only damage the blenders but also takes time to melt during which bartenders can serve more customers at quicker pace. Flake ice machines are simply faster & have better reliability.

Where Can I Get A Flake Ice Machine?

Industrial Refrigeration Pvt. Ltd (IRL) are pioneers in promoting scientifically designed, highly reliable & energy efficient flake ice systems in India.

IRL offers some of the best flake ice makers with capacity ranging from 1 ton/24 hours to 100 tons/24 hours. Industrial Refrigeration designs & erects refrigeration system in ammonia or Freon 404A incorporating the flake ice generator.

Our flake ice maker machines find application in wide ranging fields like aquatic food processing, medium and large chain supermarkets, food processing, medical facilities, concrete cooling, dye industry etc.

Feel free to contact us here for the best solution to your flake ice maker machine requirements.

Snow Room: Year Long Arctic For Your Better Health

The days are fading to the past when ‘sauna’ meant ‘hot tubs’ & ‘steam rooms’. Snow rooms, or ice rooms, are changing the experiences of traditional spas. Snow room spas offer more refreshing and soothing ambience & health benefits than their contemporary hot tubs & steam rooms.

Chill of the Arctic plus aesthetics of the Antarctic, or vice versa if you wish, conjured in a dedicated space enliven you from the inside. Snow rooms are typically used in contrast therapy in combination with a hot sauna.

These rooms are good for your wellbeing & it is good to reward your body & mind a chilled calm experience once in a while!

What Are Snow Rooms?

Snow room, also referred to as ice room or cold room, can be a room of area 5m² to 50m² with real snow at temperatures ranging from -21°C to -27°C. It is a completely sealed cabin with attractive interiors (usually the rocky aesthetics of Antarctic) creating a sort of snow cafe or ice room spa.

On the other hand, ice chutes are smaller packages which dispense ice in a neat manner and can be installed adjacent to the hot sauna for cooling you down quickly. These sauna snow rooms are definitely a stylish addition to any home or commercial spa.

Places To Set Up A Snow Room

Snow room can be set up in your house (near the bath tub if possible) as well as at a traditional spa adjacent to the hot sauna room. Some of the other applications are as follows:

- Sauna snow room spas.

- Snow cafes.

- Snow beer bar.

- Aquarium.

- Dedicated snow room.

- Snow cabin on yacht.

Health Benefits Of Snow Rooms

These rooms help build your immunity & increase your bodily awareness immensely. Owning this premium & exclusive luxury product available in the wellness market is a truly unique experience.

If done on a regular basis, alternating hot & cold treatment to the body (the contrast therapy) enhances health benefits & overall wellbeing of the body and mind.

- It instils a feeling of deep relaxation.

- Stimulates the metabolism of the body.

- It imparts strength to the blood vessels.

- Beneficial for the skin and hair.

- The respiratory track is soothed & symptoms of allergies are minimized.

- It relieves aches & pains in the body.

- Body tissues get adequate oxygen with its proper circulation.

- It also strengthens the immunity.

- It provides a good way to end your hectic day.

Industrial Refrigeration Pvt. LTD (IRL) is pioneer in promoting snow room system for entertainment industry and other applications. We specialize in manufacturing the following equipment of the snow room:

- Cooling plant.

- Pumps & fans.

- Snow-producing device.

- Trimming and thermal protection.

- Automatic machinery system.

Customers choose the snow circulation, temperature (anywhere from 21-27° C below zero) and snow cover level in the snow room. Depending on the snow amount, it must be regularly taken away. Additional effects using snow, ice, and hoar frost can also be created.

The fully automatic system allows smooth handling of the room in addition to simple operation. It also produces colorful snow through the lighting function whereas the air purifier and air conditioner create fresh and comfy atmosphere while making snow through air purification & natural cooling.

To know how we can help create your snow room, visit us at Industrial Refrigeration Pvt. Ltd (IRL).

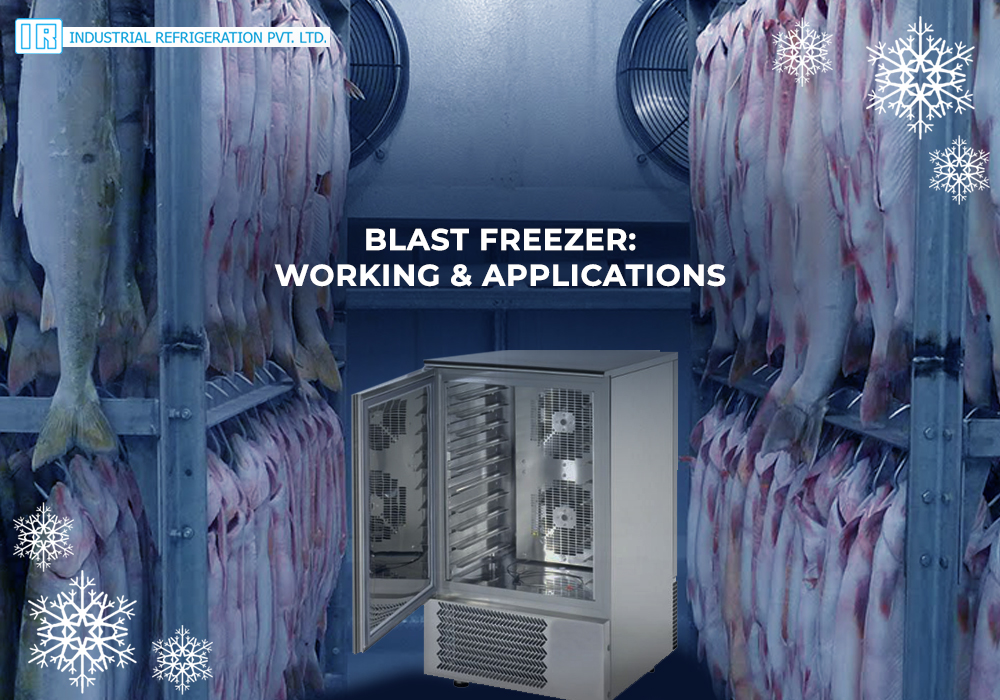

Blast Freezer: Working & Applications

What is a blast freezer?

A blast freezer (also known as shock freezer or flash freezer) is a special type of freezer storage which very rapidly freezes the food stuff or fresh produce at extremely low temperatures. This is air blast freezing.

Rapid freezing prevents the formation and growth of harmful micro-organisms in the food by neutralizing them.

Blast freezers preserve the food at extremely low temperatures (-18°C to -45°C) and for long duration whereas blast chillers cool down the food rapidly up to 3°C but only for shorter duration of preservation after which the food stock is taken out to be cooked & served.

Working principle of blast freezers

Freezing crystallizes the water inside food into ice crystals. Ordinary freezers take longer to freeze the food, consequently the ice crystals formed inside food are larger. When this ice thaws, it distorts & even damages the cell structure of food by causing phenomena like cell bursting. It affects the quality and texture of food.

Blast freezer, on the contrary, freezes the food very rapidly, and at even lower temperatures, where the blowers pass blasts of very cold air over the surface of food. The ice crystals thus formed in the food are comparatively smaller.

When food is taken out of the blast freezer (or blast chiller) and ice crystals thaw, cell structure of food is still preserved, thereby minimizing the alteration in its quality and texture.

One important aspect is to not store too high a volume of hot food inside the blast freezer which will result in higher internal temperature leading to a warmer blown air. The freezer will take longer time to first cool this stagnant air, thereby delaying the entire cooling process.

Some of the best blast freezers use movable trays which allows to customize the positioning of food to ensure its even cooling.

Blast freezing applications

Blast freezers are commercial freezers made exclusively for business owners. They need to freeze their products due to the growing production and product demand. Some of the applications of blast freezers are listed ahead.

- There are industrial blast freezers used in commercial units like cold storage companies.

- Commercial kitchens, big restaurants, hotels etc. use blast freezers as well as blast chillers to safely store food stock, cooked food and meals. Blast chillers lower the temperature of a large amount of food stock by blowing extremely cold breeze throughout the storage. This eliminates harmful bacteria from the food stock and preserves it. You can place a large stock of food in such chiller if you have to serve from it on short notice repetitively.

- Blast freezing is also employed in confectioneries to preserve large stocks of desserts/pastries which require cooling e.g. pies, cakes, puddings, ice-creams etc. Proper chilling enhances the taste and texture of the dessert

- Fishing industry & meat suppliers finds great utility in blast freezers. Sea-food decays fast if not properly preserved. In order to supply raw sea-food to distant markets of the world without compromising the quality of the haul, storing the sea-food in such freezers halts the decaying of stock for a long time.

- Vaccines contain active ingredients that are used to stimulate immunogenic response when administered to a patient. Maintaining the stability & viability of the active ingredient during production, distribution and administration of the vaccine is a huge challenge to vaccine manufacturers. Storage in a blast freezer ensures highly reduced degradation of the active ingredient making it more stable and viable for longer time.

- In dairy industry, blast chillers are used to preserve dairy items (like curd, butter, milk, flavored milk, clarified butter, cottage cheese etc.) in bulk so that they can be transported to distant places without losing quality.

Pros and cons of blast freezing

Some of the pros of blast freezing are enumerated as follows:

- Blast freezers arrest contamination of food, thus preserving food’s integrity, quality and flavor & also safeguarding its nutritional values.

- It protects delicate food preparations (like pasta, soufflés & fruit extracts) since the structure of food is preserved in blast freezing.

- Blast freezing pre-empts growth of harmful bacteria and other micro-organisms, ensuring 100% food safety.

- Blast freezers are ideal for storing large batches of leftovers thereby reducing food wastage in restos.

- Large amount of space among the trays of blast freezer ensures cold air is circulated in smooth and laminar fashion around the trays making the freezing quick and efficient.Also, dedicated compartments inside the freezer can be used to freeze store different food items for different time duration.

There are seemingly no cons for blast freezers. For domestic usage where food is preserved for lesser number of people & is consumed within short duration, a refrigerator may seem to be a more prudent choice than the blast freezers whose build, larger storage capacity, cost & power efficiency in the long run makes them best suited for commercial utility.

With the passing years, Industrial Refrigeration Pvt. Ltd. (IRL) has tied-up with global companies, like GEA Group, to introduce the latest refrigeration technologies and practices in India such as paraffin wax freezers for refineries, snow rooms, ice skating rinks, dairy refrigeration, abattoir refrigeration and modified & controlled atmosphere cold stores.

IRL caters to industries like food processing, hospitality, chemicals, oil and gas, supermarket & entertainment. Feel free to check our products and IRL will realize your refrigeration requirements.

IRPL goes live with a newly redesigned website

Having dealt in industrial refrigeration systems for so long, we’ve gained experience as to what information a client hopes to find when visiting our website. We’ve restructured our layout and are extremely pleased with the results.

Our About Us section covers our history as well as the sort of projects we’ve undertaken and the clients we’re proud to have served. The products and services on offer are displayed holistically. At a quick glance, one can find out which machines and systems are applicable in various industries.

We’re not done yet, we have a lot more content to share with you, and hope everything we display helps you gain more knowledge and make better informed decisions.

We’d love to hear your comments, thoughts and suggestions about the new site, so please visit our Contact page to leave us a message.

Thanks and happy browsing!

Industrial Refrigeration Pvt. Ltd. at the Chennai Trade Center, Nandambakkam, Chennai

Industrial Refrigeration Pvt. Ltd. would love to invite you to our stall – Number 203 – at the India International Seafood Show 2014 (http://www.indianseafoodexpo.com)

Hosted at the Chennai Trade Center, Nandambakkam, Chennai, IISS is one of the largest Seafood Fairs in Asia. Every type of stakeholder in the Seafood industry will be present under one roof, and IRPL is delighted to bring along its expertise in Seafood Processing & Storage related products and services.

Capture plus aquaculture related activities result in close to 9 million tons of seafood production in India per annum. This scale has made India a significant player in seafood exports to major countries as well, in addition to local consumption. This ever-growing production rate requires continual support and addition of processing infrastructure, and IRPL is well poised to play a part.

We carry out both consultancy services for seafood related industrial refrigeration projects, as well as provide the following machinery on requirement basis:

• Flake Ice Machine

• Cold Storage

• Walk-in Cooler

• Blast Freezer

• IQF-Plate Freezer

• IQF-Tunnel Freezer

We hope you’ll make it to IRPL Stall No. 203 at IISS! We look forward to meeting you there and hope you enjoy the fair!

Setting up of Food Processing Units

The Ministry of Food Processing Industries has launched a Centrally Sponsored Scheme of National Mission on food Processing (NMFP) in 12th Plan (2012-17) through State/UT Governments. Under the scheme of technology Upgradation/ Establishment/ Modernization of Food Processing Industries of the mission, all the eligible entrepreneurs interested to set up food processing units in the country including the districts where there is no food processing units are provided financial assistance @25 percent of the cost of plant & machinery and technical civil works. subject to a maximum of Rs. 50 lakh in general areas; 33.33 percent of the cost of plant & machinery and technical civil works, subject to a maximum of Rs. 75 lakh in difficult areas (i.e. Jammu & Kashmir, Himachal Pradesh, Uttarakhand, Andaman & Nicobar Islands and Lakshadweep) and Integrated Tribal Development Project (ITDP) areas; and 50 per cent of the cost of plant & machinery and technical civil works, subject to a maximum of Rs.100 lakh for North-Eastern States including Sikkim.

Under the above scheme of the mission, all the new applications in 12th Plan (2012-17) are received, sanctioned and funds are released by the respective State / UT Governments, for setting up of Food Processing units in the country.

This information was given by the Minister of State for Food Processing Industries Dr. Sanjeev Kumar Balyan in a written reply in the Rajya Sabha.