Horizontal Plate Freezer

IRL

Industrial Refrigeration Pvt. Ltd. Participates at ACREX India 2015

Industrial Refrigeration Pvt. Ltd would love to invite you to our stall – Number 349, Hall 2B–at South Asia’s largest exhibition on air conditioning, ventilation, refrigeration and building services at ACREX India 2015, Bangalore International Exhibition Center (BIEC) between February 26 and 28.

ACREX India is returning to Bangalore after an eventful show at Delhi where the exhibition saw participation from over 400 exhibitors and nearly 30,000 visitors.

ACREX 2015 will be hosted at India’s only LEED Certified Green Exhibition Center at Bangalore International Exhibition Center (BIEC) with over 40,000 sq mt of fully covered and air conditioned space.

Industrial Refrigeration Pvt. Ltd undertakes design and execution of turnkey projects, compressors, condensers, evaporation and polyurethane panel-based cold rooms & frozen stores in collaboration with world-renowned suppliers.

Industrial Refrigeration also carries out both consultancy services for seafood related industrial refrigeration projects, as well as sells refrigeration equipment like:

• Flake Ice Machine

• Cold Storage

• Walk-in Cooler

• Blast Freezer

• IQF-Plate Freezer

• IQF-Tunnel Freezer

We hope you’ll make it to IRPL Stall No. 349, Hall 2B at ACREX! We look forward to meeting you there and hope you enjoy the fair!

Tips to Select a Commercial Flake Ice Machine

A Flake icemaker produces ice in its most natural shape. Created at temperatures below zero degrees, flake ice is mostly used in fisheries, laboratories and industries. Flake Ice offers the best solution for maintaining perishables. For example, flake ice machines for fish preservation guarantee long-lasting freshness and natural appearance.

Flake ice is directly formed at low temperatures – they can be as cold as -8°C. Once formed, ice flakes are dry, clean, sanitary and convenient. Ice flakes have no sharp edges so they cannot damage refrigeration surfaces, hence they are easy to store and transport.F

If you are purchasing a flake icemaker for commercial purposes, consider these tips to ensure you are buying the right one to serve your business needs:

Warranty: Life expectancy and warranty are important to consider.The condenser, compressor, and evaporator plate are the three most important parts of the ice machine. No matter what a flake ice machine seller tells you, there is always that tiny chance one of these complex parts can give you an issue. Hence, always make sure that the machine carries a warranty.

Size and capacity: When choosing a commercial ice machine size does matter because it determines how much ice it can produce in a 24-hour period. This is important, as you will be able to estimate if your machine can produce enough ice flakes for the day’s requirement. You might want a small flake ice machine or a much larger industrial sized one that outputs 20 tons/24 hours.

Space and condenser type: It is very important to know the condenser of your ice flake maker. There are three types of condensers: air cooled, water cooled and remote air cooled. Air-cooled ice makers use the most energy but are usually less expensive initially than water-cooled models. Water-cooled models are far more efficient than air-cooled units and suitable for hostile installation conditions where high humidity and ambient air temperatures would virtually shut down an air-cooled machine. Remote air-cooled condensers transfer heat generated by the ice-making process outside of the building.

Power consumption: Be sure you know what your ice machine’s power requirements are before buying;else you will be forced to make electrical adjustments after you receive your unit. The power consumption/kg or ton metric gives you a good indicator as to power requirements.

Our flake ice machinesare easy to operate and consistent in operation. They have no need for adjustments during constant ice production and have no defrost cycles. They save water and overfilling, as the machines have photoelectric eyes that automatically switch off ice making, if the storage containers reach capacity. Industrial Refrigeration Pvt. Ltd. helps you identify the right industrial flake ice machine solution to suit your customized needs. IRL offers flake ice units with capacities ranging from 1 ton/24 hours to 100 tons/24 hours.Their scientific design and many years of engineering ensure high efficiency and energy saving. They’re easy to maintain, convenient to operate and have outstanding electrical controls. Do get in touch with us to learn more about our flake ice solutions.

value added machinery

Industrial Refrigeration offers Machinery to process and add value to food industries.

Hamburger Forming Line can make hamburger patty, chicken nuggets, chicken or beef steak, pumpkin patty, etc. used by KFC, McDonald, Marry Brown etc. This forming line comprises of machines for forming, battering, flouring (pre-dusting), breading, and frying.

Patty Former can fill stuffing materials, & mold, hamburger patty and chicken nuggets, etc. Stainless steel and other special materials for food are adopted for the whole machine to make it conform to the hygienic standards and HACCP standards. It is easy to clean and conforms to European safety standards. It is versatile enough to handle a wide range of raw materials.

Battering Machine coats the batter on chicken, beef, pork, fish, shrimp and other seafood through four batter curtains and the batter bath on the bottom. Batter delivery pump can feed batter of high viscosity without cutting. It has a reliable safety protection device. Connection with the forming machine, crumb feeder and frying machine enables continuous production. The machine is fully made of stainless steel.

Flouring Machine evenly coats a layer of mixed flours uniformly all over the product on the conveyor belt. Connection with the coater and crumb feeder may form product lines for different products for the sake of various processes such as flour-batter-flour, batter-flour and batter-flour-flour. Forced fan and vibrator remove excessive flour. Removable design facilitates cleaning of whole machine and meets HACCP standards.

Breading Machine coats the breadcrumb into chicken, beef, pork, fish, shrimp and other seafood. Its suitable for both small-size crumb and big-size crumb. It is equipped with frequency inverter, safety protection device and SIEMENS electric parts. The whole machine is made of stainless steel and meets HACCP standards.

Continuous Fryer can be used to fry all kinds of products, like hamburger patties, chicken nuggets, snacks, pellets, beef steak, fish steak, shrimp steak, etc. With advanced oil-water massif technology and auto filtering function which greatly prolongs oil usage life. No need for frequently changing oil. Temperature is automatically controlled. Double-layer net belt design assures frying space. Advanced mechanical allocation and controls, keeps the machine at continuous good performance.

Features :

- Fully automatic and continuous.

- Small size, easy operation.

- Very easily cleaned.

- This line can process diverse materials such as meat, poultry, beef, mutton, Seafood, fish, shrimp, vegetable, pumpkin, potato, cheese or their mixture.

- Various production procedures can be combined for producing different end-products.

- Various sizes can be made.

- Full stainless steel 304.

- Turnkey project provided from raw materials to packing.

Industrial Refrigeration Pvt. Ltd:- https://www.irl.co.in/

Wax Moulding Plant

Industrial Refrigeration are pioneers in promoting Wax Moulding systems to Chemical & Refinery Industries.

In theory the casting process is just like photography. An image is reproduced through the use of negatives and prints but in casting negatives are molds and our prints are castings.

In lost wax bronze casting the flip-flopping of the image, from negative to positive is repeated twice, first with the production of a rubber mold and a wax casting and again with the making of a ceramic mold and a bronze casting.

We start with a three dimensional sculptural image which can be sculpted in almost any material (clay, plaster, wood, stone, wax, etc.) as long as the original artwork is robust enough to withstand molding in rubber. With a suitable original in hand we are ready to start making our first negative the rubber mold.

Features :

Automatic paraffin wax slabbing with maximum block accuracy:

- Fully automated system with a slab mass accuracy of ± 0.5%.

- Typical capacities of 1.5 to 7 tons per hour.

- Designed for total plant integration.

- Suitable for food grade products.

- Depositing using mass flow meters.

- Minimal product change over times and product loss achievable.

System supply include :

- Refrigeration plant, Packing line & Palletizing.

- Installation and commissioning.

- Training programmes.

- Spares and after sales service.

Applications :

- Chemical Industry.

- Oil & Gas Industry.

- Refineries.

Industrial Refrigeration Pvt. Ltd:- https://www.irl.co.in/

Wax Moulding systems:- https://www.irl.co.in/products/wax-moulding-plant.html

Walk in Cooler

Industrial Refrigeration offers Walk in Cooler System for Hospitality, Super Market, Pharma & other sectors .

Walk-in cooler and walk-in freezer are standard modular cold room chamber to cool or freeze food, beverage, meat, fruit, vegetable, pharmaceutical material, chemical or other goods stored inside.

Different standard dimension of cold-room length, width, height for the walk-in fridge of walk-in refrigerator, chiller & freezer are available.

Storage temperature of the walk in cooler & freezer can be optional -5 ℃ or -20 ℃ for the refrigerating storage or freezing storage of fresh vegetable & fruit or frozen food.

The modular walk-in freezer & cooler cold room can easily be disassembled and reassembled if required to be moved to a different location.

The cold room panel of the walk in cooler and walk in freezer chamber is made of high density polyurethane with an average density of 40kg/m3 for good insulation.

Cam lock tongue and groove panel cold room design with gasket makes the walk-in cooler & walk-in freezer perfectly sealed.

Condensing unit and fan coil unit.

Digital thermostat enables precise temperature control.

Cooler has years of experience manufacturing walk-ins for a wide variety of uses and industries.

- Bars Pubs & Nightclubs - Beer Coolers

- Convenience - Display Coolers & Caves

- Floral - Floral Refrigerators

- Grocery - Storage Coolers & Freezers

- Hunting - Meat & Game Lockers

- Mortuary - Body Boxes

- Residential Bars - Brew Caves

- Restaurant - Foodservice Walk-Ins

- Warehouse - Cold Storage Warehouses

Industrial Refrigeration Pvt. Ltd:- https://www.irl.co.in/

Walk in Cooler System:- https://www.irl.co.in/products/walk-in-cooler.html

Vertical Plate Freezer

Industrial Refrigeration (IRL) offers Vertical Plate Freezer systems to food industries.

The product is loaded from above into the freezing stations and then freezing commences. After the required freezing time, the plates are defrosted so as to break the adhesion between plate and product, and then the frozen product is to be raised horizontally for discharge.

Features :

- Aluminum extrusion plates.

- Galvanized strong frame.

- Stainless steel cylinder.

- Stainless steel hoses and fitting.

- Integral valve.

Applications :

- Batch loading and freezing of naked fish, meats, offal’s, fruit puree and liquids.

- Suitable for land and marine application.

- Compact and hygienic design.

Industrial Refrigeration Pvt. Ltd:- https://www.irl.co.in/

Vertical Plate Freezer systems:- https://www.irl.co.in/products/vertical-plate-freezer.html

Tube ice machine

Industrial Refrigeration are pioneers in promoting Tube Ice Machine for Beverage & Super Markets.

Tube Ice Machines are designed to satisfy the varying needs of different industries and customers. Capacity varies from 1300 kg. To 40,000 kg. of tube ice per day. These machines are operational on ammonia (NH3) & Freon (R-22) as refrigerant. We supply a perfect tube ice machine no matter what’s your need, if any of our many models does not suite your need. We will gladly work with you to custom design a model that fulfill your requirement.

The unique design of our Tube Ice Machine freezes ice automatically in the vertical stainless steel tubes by the refrigerant circulating around tubes in freezer shell, the swirl of water falls from top of each tube, the hole is formed during the formation of ice because the falling film of water, freezing takes place inside the vertical tubes, as the water freezes the impurities are washed back to the sump tank to be released as and when required, when the ice in the tubes is frozen to the desired thickness. Hot gas is released automatically into the freezer shell releasing tubes of ice onto a cutter, the cutter cuts the pieces of desired preset length.

The cylindrical ice is available in three standard diameter 1.3/8” (34mm.), 1.1/8” (28mm.) & 7/8” (22mm.) standard length is approximately 1” or can be designed to customer requirement.

Features :

- Tube ice : Is thick and transparent with long storage period. It isn't likely to melt in a short time, good air permeability.

- Perfect design : Adopted 3D simulation assembly, compact structure, easy to operate and maintain.

- Health : Ice maker adopts SUS304, PE, and aluminium material to process, and rounded design, makes it easy to clean.

- Efficient performance : Special alloy material and with special heat treatment gives the ice maker optimal thermal performance.

- Full automatically : PLC system controls the ice making process.

Applications :

- Freeze drinks

- Mix wines

- Cool foodstuffs

- Make ice pastries

- Keep foods fresh etc.

Industrial Refrigeration Pvt. Ltd:- https://www.irl.co.in/

Tube Ice Machine:- https://www.irl.co.in/products/tube-ice-machine.html

snow room

Industrial Refrigeration are pioneers in promoting Snow Room System for Entertainment industries.

A "snow room" is constructed for contrast health-keeping procedures and is equipped by artificial snow producing device.

Manufacturing equipment of the "snow room" :

- Cooling plant

- Pumps and fans

- Snow-producing device

- Trimming and thermal protection

- Automatic machinery system

Snow circulation, temperature and snow cover level in "snow rooms" are chosen by customers. The temperature in the "snow room" can be 21-27° C below zero. Lower temperature doesn't give the required effect. Depending on snow amount it must be regularly taken away. Additional effects using snow, ice, and hoar frost can also be created.

The cost of Snow Room includes :

- Design work

- Original units

- Mounting

- Thermo-insulation

- Doors

- Light (optical fiber and lens elements)

- Anti-freeze system

- Starting-up and adjustment and commission

Advantages :

- All weather snowmaker for Four Seasons Allows indoor and outdoor installation and snowmaking all year round.

- Best Snow Quality Produces large volumes of fine-quality snow (close to natural snow).

- Easy Handling Allows simple operation, thanks to the full auto system.

- Colorful Snow Produces color-sensitive snow through the lighting function.

- Air Purifier and Air Conditioner Creates a fresh and comfortable atmosphere while making snow through air purification and natural cooling.

Applications :

- Equipment for snowmaking indoors all year round

- Spa sauna snow room, Snow beer bar, Snow cafe, Aquarium, Snow room

Industrial Refrigeration Pvt. Ltd:- https://www.irl.co.in/

Snow Room System:- https://www.irl.co.in/products/snow-room.html

slurry ice

Industrial Refrigeration are pioneers in promoting slurry ice systems to process industries.

Slurry ice flowable is the mixture of ice crystal and water solution (usually sea water, brine, sweet water or glycol). It is also known as fluid ice, liquid ice, and so on. There are, usually, two ways to make slurry ice. Each way has its own features and advantages. Slurry ice can be made from broken solid ice and mixing with brine or sea water. However, the mixture still contains large and sharp ice crystals with thickness 0.6-10mm. Making this kind of slurry ice requires a large amount of energy, including energy consumption for ice breaking and grinding. Slurry ice can be made in pipe type evaporator. Brine or sweet water is pumped to internal pipe by water pump and the refrigerant circulates between inner and outer pipes. Ice crystal would be formed on the evaporator inner surface, at -8 ~ -12 , and scraped down by the rotary ice scraper. The mixture of water and ice collected is slurry ice. Resulting from the heat exchange of ice phase and high heat transmission coefficient, evaporator size may be reduced eventually.

Application fields :

Slurry ice is commonly used in a wide range :

- Air conditioning.

- Packaging and Industrial Cooling Processes.

- Supermarkets.

- Cooling and Storage of Fish.

- Produce.

- Poultry and other perishable products.

Slurry ice can boost by up to 200% the cooling efficiency of existing cooling or freezing brine systems without any major changes to the system (i.e. heat exchanger, pipes, valves), and reduce the amount of energy consumption used for pumping.

Advantage fields :

Slurry ice is also used in direct contact cooling of products in food processing applications in water resistant shipping containers. It provides the following advantages:-

- Product is cooled faster - the smooth round shape of the small crystals ensures maximum surface area contact with the product and as a result, faster heat transfer.

- Better product protection - the smooth, round crystals do not damage product, unlike other forms of sharp, jagged ice (flake, block, shell, etc.).

- Even cooling - unlike other irregular shaped ice which mostly conducts heat through the air, the round shape of the slurry crystals enables them to flow freely around the entire product, filling all air pockets to uniformly maintain direct contact to cool to the desired low temperature.

Industrial Refrigeration Pvt. Ltd:- https://www.irl.co.in/

Slurry ice systems:- https://www.irl.co.in/products/slurry-ice.html

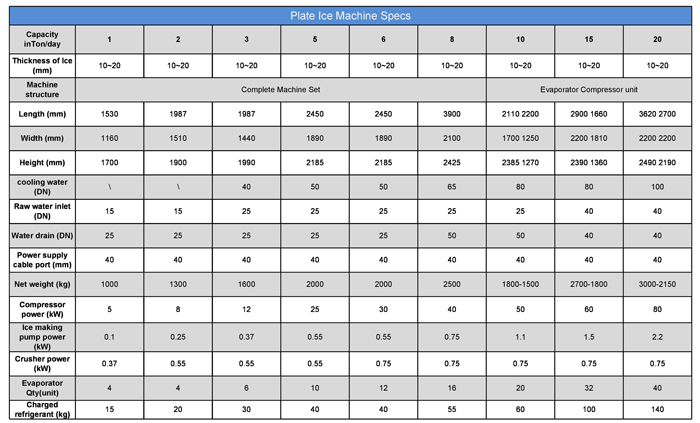

Plate Ice Machine

In Plate Ice Machines, plates of ice form on both sides of stainless steel plates. The system is easy to maintain and clean. These plates of ice are hygienic, transparent and very hard, and can be stored for long periods of time. Thickness can be adjusted up to 20mm.

Most of the parts are corrosion resistant and have a long service life. Our systems are energy efficient and operated via easy-to-use control panels. They’re self-contained systems, producing up to 20 tons of plate ice per day.

Our plate ice machines are designed to work efficiently in different working conditions, some of the core applications of our Plate Ice Machines are:

- Fish processing

- Meat processing

- Poultry processing

- Supermarket

- Laboratories, pharmaceutical

- Chemical industries

Plate Ice Machines:- https://www.irl.co.in/products/plate-ice-machine.html