Horizontal Plate Freezer

IRL

IQF-Tunnel Freezer

Industrial Refrigeration are pioneers in promoting IQF Tunnel Freezer systems to food industries.

Individual Quick Freezing (IQF) tunnel freezers precisely freeze and chill a wide range of bulk products for the food processing industry. Capable of handling 0.5 to 25 tons per hour, tunnel freezers ensure the highest degree of IQF quality and supreme freezing flexibility.

High efficiency fans and motors, and evaporators with large face areas reduce pressure drop. Optimum airflows effectively transfer heat away from your product. These innovative features provide an IQF freezing system to efficiently handle the desired product.

Features :

- Gentle mechanical fluidization.

- Broad range of bulk, flat or fragile products.

- Modular design.

- Impingement design.

- Multiple belt combinations.

- Stainless steel construction.

- Ample areas for service and cleaning.

- Frost management systems.

- Multiple temperature zones.

- Energy efficient design.

Applications :

- Small product particle range from 3/16 to 2 inch diameter.

- VEGETABLE INDUSTRY- peas, green beans, cut corn, mushrooms, vegetables, French fries, cob corn, diced carrots, diced onion, cut cauliflower, cut broccoli, cut asparagus, Brussels sprouts.

- FRUITS INDUSTRY- blueberries, cranberries, strawberries, cherries, gooseberries, raspberries, diced pineapples, sliced apple.

- SEA FOOD INDUSTRY - cooked shrimp, skin on shrimp, scallops.

Industrial Refrigeration Pvt. Ltd:- https://www.irl.co.in/

IQF Tunnel Freezer systems:- https://www.irl.co.in/products/iqf-tunnel-freezer.html

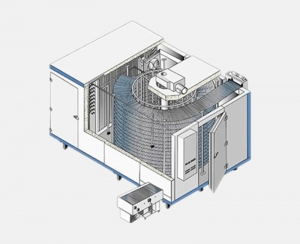

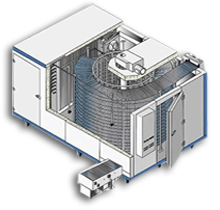

IQF-Spiral Freezer

Industrial Refrigeration are pioneers in promoting IQF Spiral Freezer systems to food industries.

Spiral freezer can freeze large quantity products in less space, especially for products which need long holding time, such as meats. Based on your site space, you can use single drum or double drum. Spiral freezer is widely used for all kinds of products. The Structure of single drum spiral freezer is compact and its capacity is 250kg/h-3000kg/h.

The freezer is a continuous in-line-belt freezer designed to minimize product weight loss and assure quality gentle handling during the freezing process. Completely factory assembled, tested, and disassembled into components to be easily shipped to plant for re-assembly. Frame & Belt supports can be constructed with economical Hot Dipped Galv. Steel or fully Stainless Steel version.

Features :

- Stainless steel product belting.

- High efficiency aluminum coils or MS Hot dip galvanized coils.

- High efficiency airfoil fans.

- Factory assembled modules. No site assembly of components.

- Aluminum and stainless steel constructed.

- Easy access to sanitation and maintenance.

- Safe, trouble-free operation.

Applications :

- POULTRY INDUSTRY - chicken parts, chicken patties, chicken nuggets, marinated chicken chunk, breaded chicken parts.

- RED MEAT INDUSTRY - meat patties, meatballs, raw hamburger, breaded fried cuts.

- BAKERY PRODUCTS - pizza crust, pie, cookie, pasta, bread dough.

- PREPARED FOODS - packaged food in trays, shrimp in trays, ice cream cups, products requiring a long retention time.

- SEA FOOD INDUSTRY - cooked shrimp, skin on shrimp, scallops.

Industrial Refrigeration Pvt. Ltd:- https://www.irl.co.in/

IQF Spiral Freezer systems:- https://www.irl.co.in/products/iqf-spiral-freezer.html

IQF-Fluid Bed Freezer

Industrial Refrigeration are pioneers in promoting IQF Fluid Bed Freezer systems to food industries.

Fruits and vegetables are usually presented to the consumer in an IQF form (Individually Quick Frozen) i.e. they are free flowing from the bag so exact amounts can be used as required. In the unfrozen state they are also of a delicate nature requiring gentle handling to minimize damage and preserve their natural appearance. These specific demands led to the development of air blast freezers employing the fluidization principle.

Fluidization is a method whereby solid particles float in an upward directed flow of air. If the air is at sub zero temperatures, say minus 350C, you have a combined method of gentle conversation and fast freezing. These freezers are generally supplied with stainless steel wire mesh belts to assist the movement of larger products through the freezer, but fluidization is still achieved. Two belts are employed, the first to freeze the outer crust of the product (case harden as it is often called), the second to complete the freeze process. The belts are of variable speed such that the bed depth and retention times of the product in the tunnel can be altered.

Features :

- Stainless steel product belting.

- High efficiency aluminum coils or MS Hot dip galvanized coils.

- High efficiency airfoil fans.

- Factory assembled modules. No site assembly of components.

- Aluminum and stainless steel constructed.

- Easy access to sanitation and maintenance.

- Safe, trouble-free operation.

Applications :

- VEGETABLE INDUSTRY : peas, green beans, cut corn, mushrooms, vegetables, French fries, cob corn, diced carrots, diced onion, cut cauliflower, cut broccoli, cut asparagus, Brussels sprouts.

- FRUITS INDUSTRY : blueberries, cranberries, strawberries, cherries, gooseberries, raspberries, diced pineapples, sliced apple.

- SEA FOOD INDUSTRY : cooked shrimp, skin on shrimp, scallops.

| Item Model |

Capacity Kg/h |

Ref. Cap. kw |

T. Motor kw |

T. Time Min |

Temp.in Deg. |

Temp.out Deg.C |

Temp.Deg .C |

RFNT | Overall Dim. |

|---|---|---|---|---|---|---|---|---|---|

| SNNF-150 | 150 | 30 | 12 | 15-60 | +15 | -18 | -35 | R717/R22 | 6.8X 2.7 X 2.7 |

| SNNF-250 | 200 | 48 | 15 | 6 X 2.7 X 2.7 | |||||

| SNNF-500 | 500 | 85 | 20 | 12 X 2.7 X 2.7 | |||||

| SNNF-750 | 750 | 130 | 30 | 17 X 2.7 X 2.7 | |||||

| SNNF-1000 | 1000 | 175 | 40 | 22 X 2.7 X 2.7 | |||||

| SNNF-1500 | 1500 | 220 | - | 22 X 3.7 X 2.7 | |||||

| SNNF-2000 | 2000 | 340 | - | 21 X -1.7X 2.7 |

Industrial Refrigeration Pvt. Ltd:- https://www.irl.co.in/

IQF Fluid Bed Freezer systems:- https://www.irl.co.in/products/iqf-fluid-bed-freezer.html

Ice Skating Rink

Industrial Refrigeration are pioneers in promoting Ice Skating System for Entertainment industries.

Ice skating is an excellent recreational activity and sport that can engage children and people of all ages. For centuries it has been a popular form of entertainment for all economic classes. It can be done for a variety of reasons, including leisure, travelling, and various sports. Ice skating occurs both on specially prepared indoor and outdoor tracks, as well as on naturally occurring bodies of frozen water such as lakes.

Now-a-days Ice skating rinks having being set up inside shopping malls, has made ice skating the new, most sought after activity of amusement. Here you can, not only simply relish your ice skating on well set up ice floor, at the same time you can also relish the buying of meals, drinks, clothes, gadgets etc. at the food court, hypermarkets & the various outlets. Thus, achieving a perfect fun-filled time with family and friends alike.

Advantages :

The aluminium ice rink has the following advantages :

- 100% ice guarantee up to + 25 C°/ wind 1 m/s.

- Best ice at poor weather conditions and ambient temperatures, for example at warm weather spells.

- Optimal conductibility, the thermal conductivity of aluminium is 1000 times better than the thermal conductivity of rubber.

- Extremely low energy consumption.

- Very short installation and dismantling time.

- Good price performance ratio.

- Fast ice formation.

- Strength, very solid system.

- Stability, ice formation also below the cooling tubes, thus no holes in the ice.

- Time-tested quality.

- Ecologically friendly.

- Environmental management system, commensurate to the ISO 14001 standard.

- The whole power consumption of your aluminium ice rink is compensated with CO2 neutral green energy from our windmill-powered plants.

Industrial Refrigeration Pvt. Ltd:- https://www.irl.co.in/

Ice Skating System:- https://www.irl.co.in/products/ice-skating-rink.html

Horizontal Plate Freezer

Industrial Refrigeration offers Horizontal Plate Freezer systems to the food industry.

The Products are simply placed into the Horizontal pockets between the aluminum freezing plates in batches; the plates fall horizontally to give true double contact freezing. Once the freezing cycle is completed, the plates are lifted and opened, and then the product can be unloaded; after fresh product is loaded, the whole cycle can be continuous.

Features :

- Aluminum extrusion plates

- Galvanized strong frame

- Stainless steel cylinder

- Stainless steel hoses and fitting

- Integral valve

- Capacity from 800~2000kgs per batch

Applications :

- Batch loading and freezing of naked fish, meats, offal’s, fruit puree and liquids

- Suitable for land and marine application

- Compact and hygienic design

Industrial Refrigeration Pvt. Ltd:- https://www.irl.co.in/

Horizontal Plate Freezer systems:- https://www.irl.co.in/products/horizontal-plate-freezer.html

Flake Ice Machine

Industrial Refrigeration (IRL) are pioneers in promoting flake ice systems in India.The surface area of flake-ice is quite large and covers the product properly. Also being thin, they do not damage the delicate fish skin. The temperatures of the flakers are almost -4° to -5°C. With these excellent characteristics, flake ice is always used in the processing industries. It plays an important part in sea food industries which is one of major users of flake ice. It is mandatory that any seafood industries should have a flake ice unit based on the production of the sea food in the ratio of 1: 2. Flake ice is used in Dye making. It also plays an important role in concreting. It is important to keep the concrete mix at low temperature to yield superior concrete and to avoid any cracks in concreting. Smaller ranges of flake ice units are made suitable for sea water and can be supplied to Deep sea trawlers & small units within ranges of 1 to 2 tons/24 hrs.Ice flakes are also used in supermarkets.

IRL offers Flake ice units with capacity ranging from 1 ton/24 hours to 100 tons/24 hours. Industrial Refrigeration designs & erects refrigeration system in ammonia or Freon 404A incorporating the flake ice generator.

Application Fields :

- Fishery and aquatic food processing

- Medium and large chain supermarket

- Mine temperature reduction

- Food processing

- Preservation and cooling field application

- Skiing & other sports

- Medical facilities

- Concrete cooling project.

- Dye's chemical industry.

Features :

- Scientific design and many years of engineering experience

- Safety and sanitation

- High reliability and low breakdown rate

- High efficiency and energy saving

- Simple maintenance and convenient operation

- Great adaptability

- Outstanding electric control system

Flake Ice advantages :

- Directly formed at low temperatures. Ice flakes are as cold as -8°C.

- Once formed, Ice flakes are dry, clean, beautiful in shape. Sanitary and convenient.

- Relatively big contact area and good mobility can ensure their full contact with refrigerated objects to realize good preservation effect.

- Without any acute edges and damage concerns. Ice flakes cannot damage the surfaces of refrigerated objects but are extremely suitable for storage and delivery.

Flake Ice Machine

Flake Ice Maker

Medium-sized flake ice machine model and performance parameter

| Model | Capacity | Refrigeration Capacity | Evaporating Temp. | Reducer Power | Circulating pump power | Compressor | Weight |

|---|---|---|---|---|---|---|---|

| IR30 | 3000kg/d | 14100kcal | -22 ℃ | 0.37kw | 0.03kw | 12hp | 1022kg |

| IR40 | 4000kg/d | 18800kcal | -22 ℃ | 0.37kw | 0.03kw | 20hp | 1117kg |

| IR50 | 5000kg/d | 23500kcal | -22 ℃ | 0.55kw | 0.12kw | 25hp | 1168kg |

| IR60 | 6000kg/d | 28200kcal | -22 ℃ | 0.55kw | 0.12kw | 30hp | 1168kg |

| IR80 | 8000kg/d | 37600kcal | -22 ℃ | 0.75kw | 0.25kw | 40hp | 1650kg |

| IR100 | 10000kg/d | 47000kcal | -25 ℃ | 0.75kw | 0.25kw | 50hp | 1742kg |

| ★ Note: For non-standard demand, please inform us the details. | |||||||

Industrial Refrigeration Pvt. Ltd:- https://www.irl.co.in/

flake ice systems in India:- https://www.irl.co.in/products/flake-ice-machine.html

Fish Processing Machinery

Industrial Refrigeration(IRL) offers Fish Processing Machinery to Fish Process Industries.

IRL plans, designs and set up complete processing lines as well as fish processing facilities ashore or on board ship. Conversions, extensions and modernization and retrofitting are also offered by IRL.

Products :

Gutting machines minimize waste percentage by gutting basically all kinds of fish with very high precision leading to reduction of your production cost.

IRL offers a series of standard machines, but can also produce customized machines to match your requirements.

The gutting of fish must be thorough, but at the same time the machine must be easy to maintain, flexible to adjust and suitable for different types of fish. In a few words, that is the GUTMASTER.

Machines for processing fish it is all about making sure that the customers get a higher output from their raw materials.

Precision and high capacity are key words for FILETMASTER.

When the fish is gutted and cut, the guts are sucked out with the help of vacuum. This way problems involving knife sharpening as a result of stones that fish have swallowed are eliminated.

FILETMASTER can produce both single and butterfly fillets after minor adjustments.

To optimize yield, HEADMASTER removes the head of each fish with a U cut. The cut is made around the collarbone up to the neck.

The ergonomics for the two operators has been in focus during the design phase. The handling of the fish takes place within the operators' reach and they do not have to reach far away when they have to place them into the bowls of HEADMASTER. This ensures good ergonomics for the operators and allows for high capacity when processing fish.

Good hygiene is an integral part of producing foodstuff and given the fact that the raw material is often transported over large distances before being processed, washing is often necessary.

WASHMASTER can be used for initial washing, rinsing during production or final washing before packaging.

WASHMASTER is available as a 2-chamber system so that it is possible to reuse some of the water while there is still fresh water in the second chamber.

We offer a range of filters for WASHMASTER.

The Scalemaster machine is mounted on a solid frame with spring suspension so that it adjusts to the size of the fish.

The descaling is done by rotating brushes that are driven by hydraulic motors and the speed of the machine can be adjusted by pressing the control panel on the front.

The descaling process works better without water but taking the cleaning of the brushes into consideration, a limited amount of water may be used. The water consumption of the machine can be adjusted to suit the operator’s requirements.

During the descaling process the fish is held in place by strong ties – holding the fish in place is important to achieve a good descaling. The tightening of the ties is done pneumatically and the tightening process can be adjusted smoothly. The ties can be removed in a minute for easier cleaning of both the ties and the machine.

Scales and water run down and out of the machine, making it easy to collect and filter the scales from the water. The collection of the scales is done in a filter system that can be easily emptied and cleaned.

Industrial Refrigeration Pvt. Ltd:- https://www.irl.co.in/

Fish Processing Machinery:- https://www.irl.co.in/products/fish-processing-machinery.html

Deep Freezer

Industrial Refrigeration (IRL) offers Deep Freezers to the food industry.

Deep Freezers, Upright Ultra Cold Deep freezers, refrigerators, in different sizes, configurations, temps to -85C, for clinical trials, benchtop or Under counter freezers and fridges. Also carry Pass - Through freezers and fridges, blood and plasma units, fridges and chests, -30C freezers, -45C freezers and -85C freezers, Flammable Storage units, -40 freezers for premixed frozen epoxies, standard or custom.

Features :

Chamber interior is fabricated of stainless steel with dull finish & exterior is of stainless steel / G.I. Powder coated. The inner working chamber is water & vapour tight high-grade stainless steel. All seams are arc-welded & passivated for strength & durability.

Application :

- Chemical Industry

- Oil & Gas Industry

- Refineries

- Hospitality

Industrial Refrigeration Pvt. Ltd:- https://www.irl.co.in/

Deep Freezers:- https://www.irl.co.in/products/deep-freezer.html

Cold Storage

Industrial Refrigeration(IRL) offers Cold Room Systems to food industry.

IRL specialized in design and installation of cold rooms & cold stores. Our experts are available to guide you through each stage of the process from the initial consultation through to the design and then the final installation. This ensures that the cold room you have specified meets with your expectations and requirements.

Design & Consultation : We offer an initial consultation, with design advice, CAD drawings and a full quotation as part of the project package. We can also offer a consultation service for the design of insulation and refrigeration systems, if you wish to appoint your own contractor.

Insulation : All our cold stores in this section are constructed using the latest fire resistant tech rated panels. Rooms up to 10m in height and any combination of widths and depths can be built meaning whether you want to walk in or drive in, we can build a cold room to suit your needs.

Refrigeration : All types of temperature controlled systems can be designed and installed by our engineering department. All temperature ranges from ambient, preparation areas, chillers and freezers can be achieved. We design remote systems using the latest low noise equipment to achieve the temperatures you require. We are pride of ourselves of offering global warranty, service and support and are adequately able to offer annual comprehensive maintenance post warranty.

Floors : A range of floor options including insulated floors with EPS slab & Puf slab for cold room, vapour barrier, Trimix concrete finish larger rooms are all available.

Doors : A full range of door options are available and are manufactured to order which means we can offer any size and type of door you require. Hinged, sliding, rapid roll, crash, flush, incorporating vision panels and windows are just a selection of the products available.

Optional Extras : As part of the design and installation package we can offer racking, lighting, strip curtains, humidity controls, camera and many other additional items.

Industrial Refrigeration Pvt. Ltd:- https://www.irl.co.in/

Cold Room Systems:- https://www.irl.co.in/products/cold-storage.html

Chilled Water System

Industrial Refrigeration offers Chilled Water System for food, pharma, & chemical industries.

IRL manufactures Water Cooled Screw Chillers incorporating reliable screw compressors from Bitzer (Germany) and Frascold (Italy). These chillers are fully Microprocessor based suitable for process cooling applications from (+) 20˚C up to (-) 40˚C. For lower temperatures of up to (-) 50C look into Brine Chillers. These screw chillers are offered with up to 2 Nos. screw compressors in one machine but having separate and individual refrigeration circuits. These chillers are world class, manufactured in an ISO 9001, certified factory with an option of using CFC free refrigerants R-407C & R-134a complete with in-built Process pump and stainless steel chilled water expansion tank. These chillers are also rated for an ambient of up to (+) 50˚C and cooling tower water temperature up to (+) 37˚C at the inlet of the condenser. The various operating voltages of these chillers are: a) 380 / 400 Volt AC / 50 HZ b) 460 Volt AC / 50 HZ c) 380 Volt AC / 60 HZ d) 460 Volt AC / 60 HZ.

Features :

RELATED ALL TYPE CHILLER The glycol chillers, brine chillers, air cooled brine chillers, water cooled brine chillers and liquefiers offered by IRL are tailor made to suit customer requirement. IRL offers these low temperature Glycol / Brine up to an operating temperature of (-)50˚C for which compressors can be single stage open type / double stage open type / double stage semi hermetic / single stage screw depending on the size and the temperature requirement of the customer. For very low temperature application even Cascade systems are used for quick cooling. The material of construction is selected carefully depending on the application temperature and special alloys steel is used for ultra lower temperature application. These chillers can be air-cooled or water-cooled depending on the customer requirement. These chillers are rated for an ambient of (+) 480C and various operating voltages which are: a) 380 / 400 Volt AC / 50 HZ b) 460 Volt AC / 50 HZ c) 380 Volt AC / 60 HZ d) 460 Volt AC / 60 HZ

Applications :

- Food processing industry

- Accelerating mould of plastic.

- Extending the life-span of mechanical components.

- Electronic industry and ultrasonic cleaning industry.

- Electroplating industry cooling to enhance precision of electroplating.

- Food processing industry cooling to enhance the quality of food.

Advantages :

- Water temperature can be set at random from 0.5 degrees to 20 degrees.

- Intelligence control system can automatically adjust the load increasing and decreasing of the compressor to maintain outlet temperature in certain degree based on water temperature.

- The flow of water varies from 1.5m3/h to 24m3/h, which can meet different needs.

- Containerized structural design, which can be transported to places where refrigeration is needed.

Industrial Refrigeration Pvt. Ltd:- https://www.irl.co.in/

Chilled Water System:- https://www.irl.co.in/products/chilled-water-system.html