Where there is fish stored, there has to be ice for fish preservation. Keep it fresh, Keep it cool, with IRL’s Flake Ice Machine for fish companies.

Flake ice is known for its cleanliness and purity, making it ideal for food-related applications. Unlike other forms of flakes of ice, flaky ice is made using a process that eliminates impurities and ensures high levels of hygiene, making it safe for direct contact with food products. The irregular shape and thinness of flake ice allow for more uniform cooling of products compared to other types of ice. This helps prevent hot spots and ensures consistent temperature control, which is crucial for ice preservation and for preserving the quality and freshness of perishable goods.

Flake-ice is considered to be highly economical over crushed ice which melts at a higher rate during loading and storage. Large surface area-to-volume ratio of flake ice allows it to cool products more quickly than other types of ice. It is easy to dispense and distribute which makes it convenient for various applications, from filling beverage glasses to packing and shipping perishable goods.This rapid cooling property and versatility of flake ice ensures maximum freshness and preserves the quality of the fresh produce.

Upon impact with the product, flake ice does not cause damage to the product itself; instead, the ice breaks upon contact, safeguarding the integrity of the product. The softness and moldability of flake ice makes it ideal for applications where conformability is necessary, such as in physical therapy or cold therapy packs. Flake-ice holds less than 2% residual water content making it dry and the coldest form of ice. It has irregular fragments of ice with a variable thickness that can be adjusted between 1 to 2 mm.

These features of flake ice make its application ideal for industrial processes, fish & seafood display cabinets in supermarkets, transportation of perishable goods, as well as for optimising dough temperature in the baking industry.

What makes Industrial Refrigeration Pvt. Ltd. Flake Ice Machine Reliable & Durable?

Several decades ago, Industrial Refrigeration Pvt. Ltd. (IRPL) recognised this difference and pioneered the application of flake-ice to the seafood industry, long before the Government of India made it mandatory (HACCP) for its use in the export oriented fish processing industry.

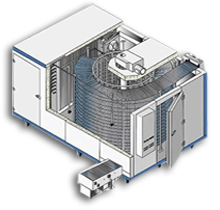

IRPL also offers complete food processing plants, Individual Quick Freezers (IQFs) & ultra modern multi product cold storages on a near-turnkey basis, having successfully executed several turnkey and ice making projects across India and overseas. This includes 10 ice-makers projects of 10 tons, each installed under one roof for a seafood park in Kerala and one for a fishing harbour in Oman. IRPL offers a complete flake-ice plant (generator drum + refrigeration system), or separate ice generators in case a refrigeration system preexists in your premises.

Features:

- Scientific design inspired from years of engineering experience

- Quick ice production

- Safety and sanitation

- High reliability and low breakdown rate

- Compact design

- High efficiency and energy saving

- Simple maintenance and convenient operation

- Great adaptability

- Outstanding electric control system

Whether you need a standalone unit for a small seafood display cabinet or a large-scale flake ice plant for industrial processing, there are options available to meet your specific requirements.Our in-house refrigeration solutions (particularly for food processing) draws upon engineering expertise from leading global companies in Freezing Technology to keep abreast of the technological innovations.

Technological Specifications:

Medium-sized flake ice machine model and performance parameter

| MODEL | CAPACITY | REFRIGERATION CAPACITY | EVAPORATING TEMP. | REDUCER POWER | CIRCULATING PUMP POWER | COMPRESSOR | WEIGHT |

| IR30 | 3000 kg/d | 14100 kcal | -22 ℃ | 0.37kw | 0.03kw | 12hp | 1022 kg |

| IR40 | 4000 kg/d | 18800 kcal | -22 ℃ | 0.37kw | 0.03kw | 20hp | 1117 kg |

| IR50 | 5000 kg/d | 23500 kcal | -22 ℃ | 0.55kw | 0.12kw | 25hp | 1168 kg |

| IR60 | 6000 kg/d | 28200 kcal | -22 ℃ | 0.55kw | 0.12kw | 30hp | 1168 kg |

| IR80 | 8000 kg/d | 37600 kcal | -22 ℃ | 0.75kw | 0.25kw | 40hp | 1650 kg |

| IR100 | 10000 kg/d | 47000 kcal | -25 ℃ | 0.75kw | 0.25kw | 50hp | 1742 kg |

★ Note: For non-standard demand, please inform us of the details.

Headquartered in Mumbai, IRPL is a part of the 65 year old ALLSTATE Group involved in Refrigeration, Transformers, Leisure Equipment, Software & Media. Some of our group companies have agreements with Fortune 500 Companies viz Fuji, Agfa, Chemours (Du Pont), and other International Companies.