Industrial Refrigeration are pioneers in promoting Wax Moulding systems to Chemical & Refinery Industries.

In theory the casting process is just like photography. An image is reproduced through the use of negatives and prints but in casting negatives are molds and our prints are castings.

In lost wax bronze casting the flip-flopping of the image, from negative to positive is repeated twice, first with the production of a rubber mold and a wax casting and again with the making of a ceramic mold and a bronze casting.

We start with a three dimensional sculptural image which can be sculpted in almost any material (clay, plaster, wood, stone, wax, etc.) as long as the original artwork is robust enough to withstand molding in rubber. With a suitable original in hand we are ready to start making our first negative the rubber mold.

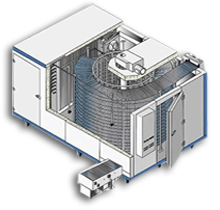

Features :

Automatic paraffin wax slabbing with maximum block accuracy:

- Fully automated system with a slab mass accuracy of ± 0.5%.

- Typical capacities of 1.5 to 7 tons per hour.

- Designed for total plant integration.

- Suitable for food grade products.

- Depositing using mass flow meters.

- Minimal product change over times and product loss achievable.

System supply include :

- Refrigeration plant, Packing line & Palletizing.

- Installation and commissioning.

- Training programmes.

- Spares and after sales service.

Applications :

- Chemical Industry.

- Oil & Gas Industry.

- Refineries.

Industrial Refrigeration Pvt. Ltd:- https://www.irl.co.in/

Wax Moulding systems:- https://www.irl.co.in/products/wax-moulding-plant.html